Walk a Mile In Her Shoes

WINNER: 2019 Design & Innovation Award (ROI of Human-Centered Design)

Solutions for In-Store Teammates, Buy Online, Pickup In Store

This case study is presented with the consent of my fellow design, product, and engineering teammates on the Fulfillment product team, with whom I had the pleasure of leading and collaborating while this solution was developed. Work shown is the property of DICK’S Sporting Goods, Pittsburgh, PA

1. Challenge

Customers (known as “Athletes” within DICK’S Sporting Goods) expect their Buy Online Pickup In Store (BOPIS) experience to be fast & easy. In order to meet the expectation of our athlete’s order being fulfilled quickly, our store managers were told that 100% of orders need to be ready for pickup in less than 15 minutes. Initial store visits from the Fulfillment product team revealed that our Teammates (in-store co-workers) were very apprehensive about the new target time.

2. Design Thinking Process

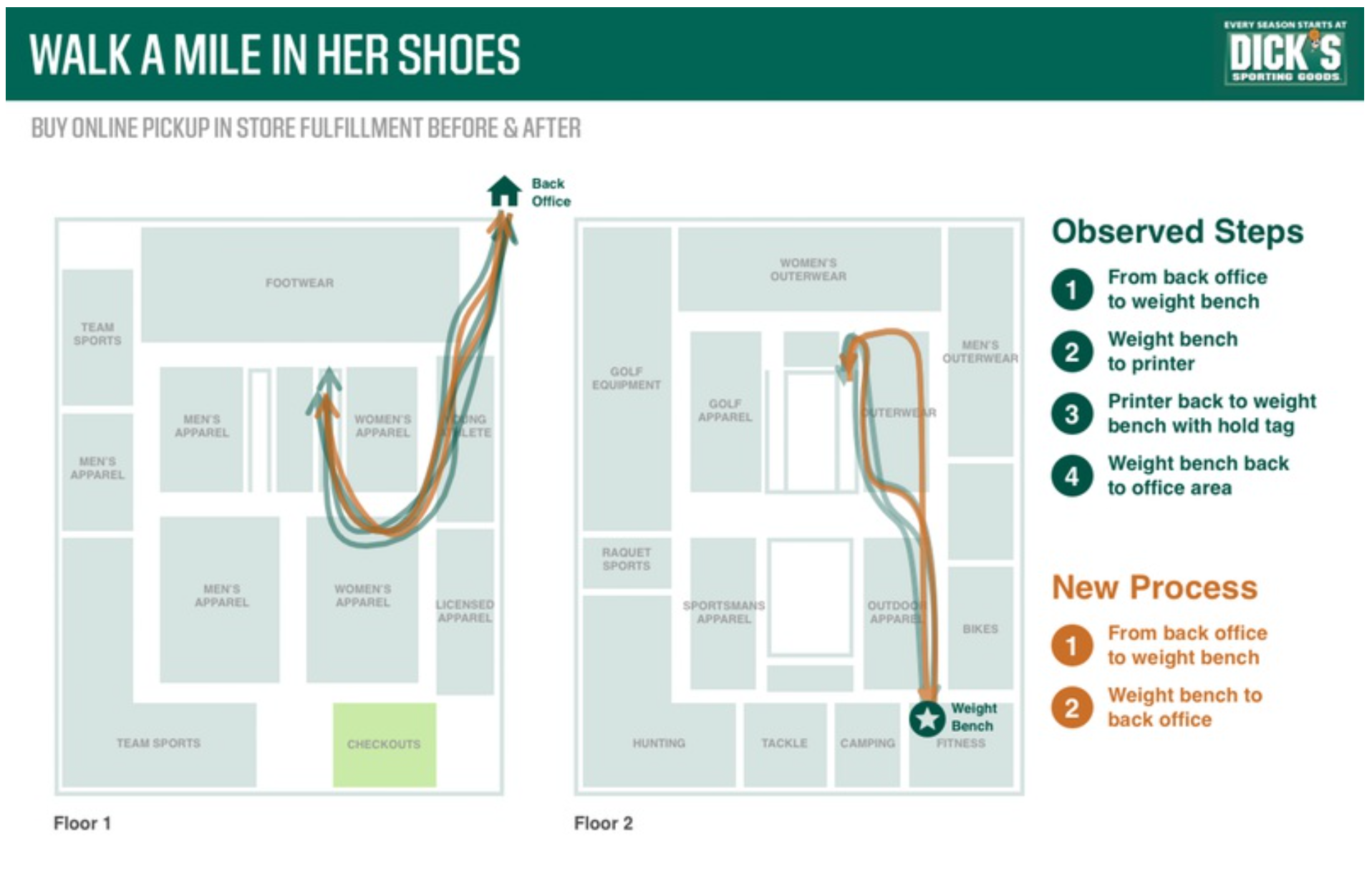

During weekly store research trips, the product team recorded the pains and goals of our teammates. We honed our research and created personas to guide our concepts. We created the idea of our teammates using a “shot clock” in the fulfillment app so they would know how much time they had left to hit the <15 minute goal. A prototype of this concept was created and brought to a store, and the timer was viewed positively...until an order came in for a heavy weight bench. The team watched as a store teammate (Ashley) walked up and down flights of stairs and manually entered UPC numbers into a desktop computer in a back office to complete the order. She had traversed hundreds of yards and four flights of stairs to get this order packed, and she did so with purpose as she wanted to make good on the <15 minute BOPIS pack metric. The teammate was followed during the entire process, and we felt the stress of the shot-clock winding down. Ashley didn't need a way to see how long the process was taking, she needed a process that didn't take so long!

3. Implementation & Solutions

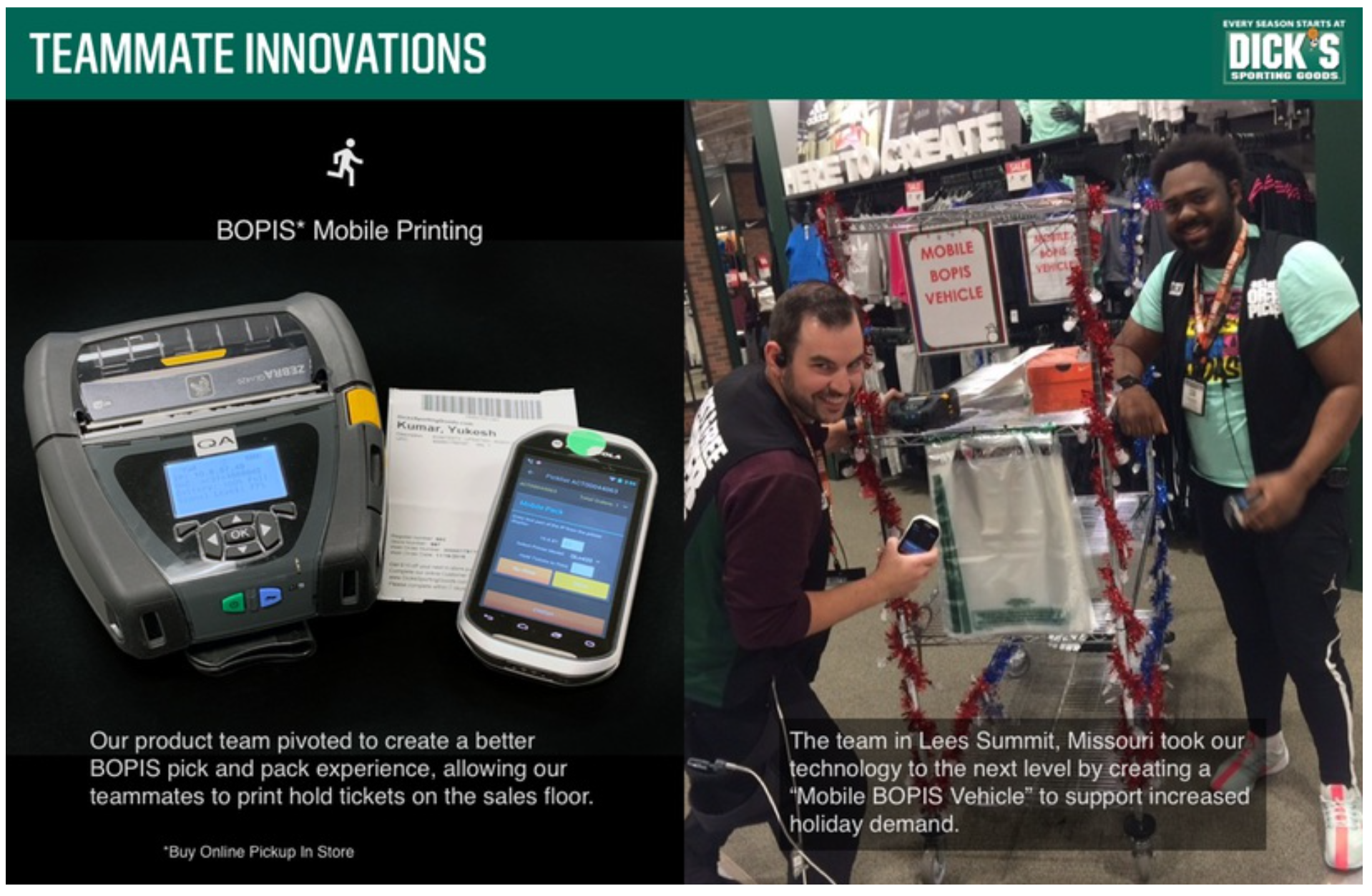

Our research and testing lead us to create the ability for our teammates to complete a BOPIS order using a mobile device and a mobile printer. No more trips to a desktop computer in a back office to print a hold ticket. We piloted the feature in one store, then five, and then to the Dallas East district. Store feedback lead us to expand our functionality to accommodate smaller stationary printers that could be placed strategically near the BOPIS pickup area. Our teammates could now tap the print button after finding the item and immediately notify our athletes that the order is ready. Word spread quickly amongst the stores and we soon had many reaching out to us to be a part of the pilot. We rolled the feature out to our top 300 BOPIS stores just days before the annual holiday rush. After the rollout, we watched our teammates innovate on top of our technology and create entirely new concepts like the “Mobile BOPIS Vehicle” from Missouri.

4. Results

“Order Placement” to “Ready for Pickup” duration times dropped from 97 minutes to 14 minutes.

75% of orders are now ready in less than 10 minutes, 50% ready in less than 6.

Avg. 2.68 minutes less effort, per order, to pick & pack for our Teammates.

72.9% adoption within the first week, 81.4% sustained usage over 4 months, currently now in use by all stores and teammates nation-wide.

Just shy of half-a-million BOPIS orders packed in the first 4 months alone.

A 36% increase in throughput gain in Ship from Store (SFS) efficiency. Essentially, having an alternative avenue to pack BOPIS orders relieved significant pressure from the Ship from Store packing flow.

Zero to One: From observation to MVP (Minimally Viable Product) in 64 days. MVP to chain-wide value-add in just 33 days.

Durability: 1 defect logged during initial rollout, zero downtime reported.

As word spread of the success of the new mobile application and equipment, teammates continued to provide suggestions for the software as well as innovative uses for the printers and mobile carts, including the addition of battery packs and fold-out tables. At our annual store leadership conference in 2019, there were lines of store managers waiting to tell us their specific stories, all based on the excitement for having a team that designed for their needs, not just the needs of the bottom line. And of course, we loved being able to take their latest ideas and validate them for future iterations!